Minimize downtime with proactive maintenance scheduling

Mine Scheduler is Designed for Mobile Maintenance Teams

Boost maintenance efficiency with minimal disruptions

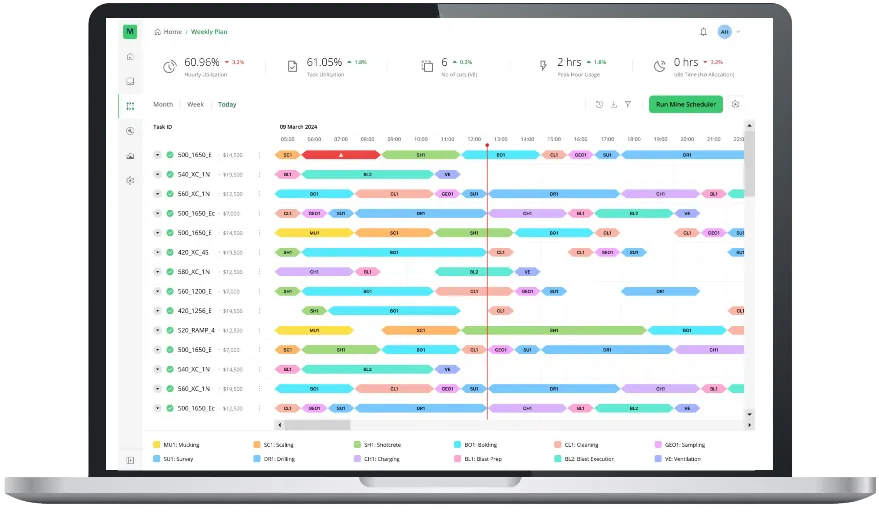

Identify Deviations Quickly

Link every activity on-site to equipment and stope, so you can see exactly what is happening in real time, when, and why. Deviation labels such as “No independent guidance”, “Lost signal”, or “Breakdown – Mechanical” are explicitly captured in the system.

Leading Indicator Triggers

Alerts are automated for when downtime or deviations reach a threshold mid-shift, so that corrections happen proactively, instead of only after a breakdown has already taken place.

Visualize Windows of Opportunity for Preventive Maintenance

Mine Scheduler quickly identifies the best windows of time for maintenance teams to intervene or carry out repairs or inspections – allowing minimal disruptions to on-site operations.

Why Maintenance Teams Choose Mine Scheduler

Who is Mine Scheduler for?

Mine Supervisors

Gain real-time visibility of resources at the mine face.

Short Term Planners

Visualize the 24-hour cycle to easily identify opportunities and interventions in shifts.

Control Room Operators

Identify systemic deviations quickly with a holistic data interface.

Mobile Maintenance Planners

Gain a bird’s eye view of equipment performance for proactive maintenance routines.