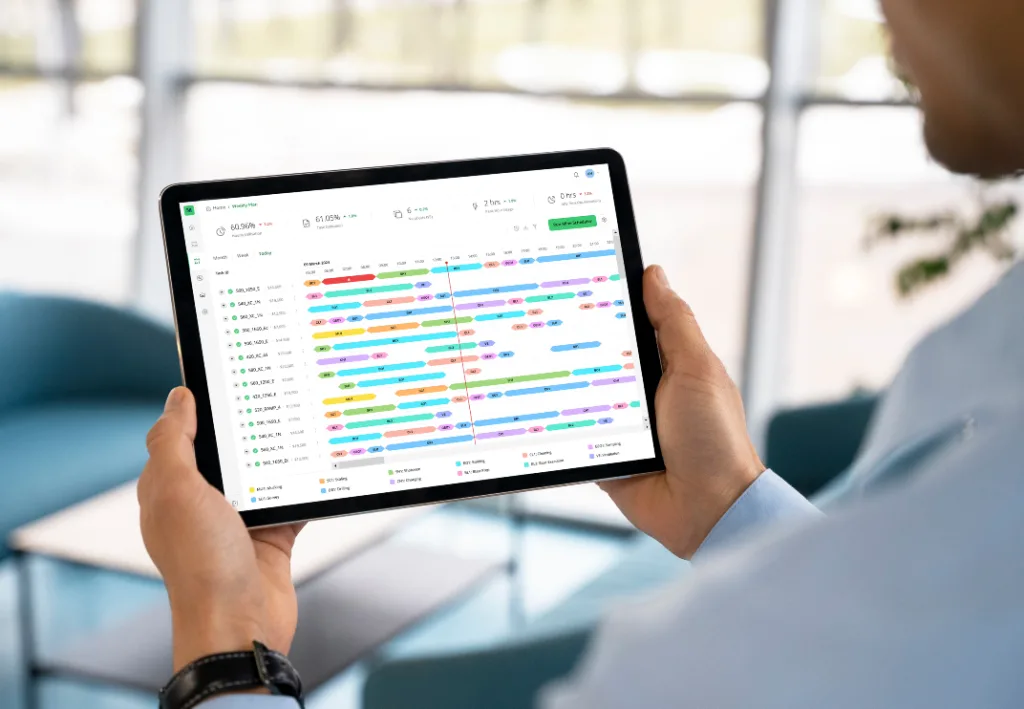

Identify systemic deviations quickly with a holistic data interface

Mine Scheduler is designed for Control Room Operators

Enhanced data visualization, faster response times

Root Cause Grouping

Identify root causes for recurring issues more quickly with an auto-classifying function for any deviations from the mine plan. Conversely, spot top drivers and operators, prioritizing communication of vital information in emergency situations to top performers.

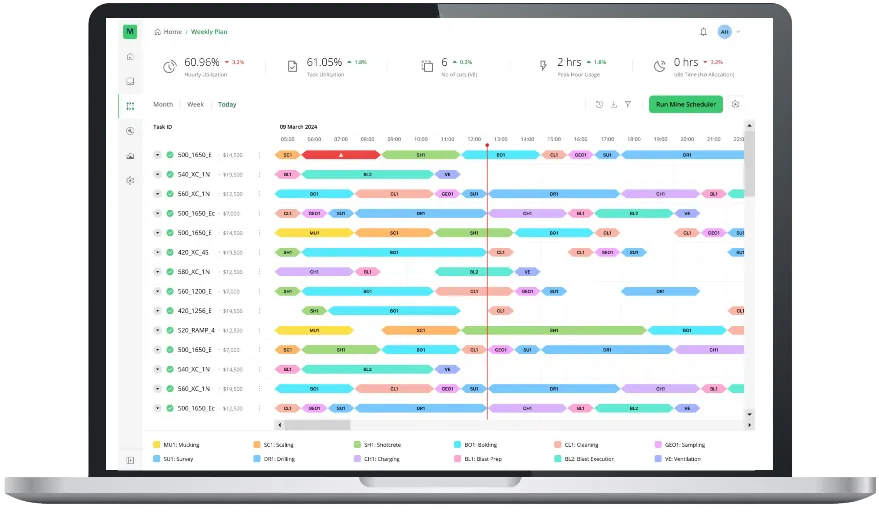

Heatmaps or Trend Views

Data is collated and aggregated into trend and heatmap views across shifts to identify the stops, equipment failure or delay types that are systemic.

Integration with Mining KPIs

Tie production tons, utilization rates, plan adherence and other KPIs into the same visualization for a one-glance dashboard. Operators can then determine whether the shift is on pace to meet tonnes and schedule.

Why Control Room Operators

Choose Mine Scheduler

Unlike most short interval control systems that require proprietary software, YCP Unison leverages Microsoft products like Power BI and Power Query, making it easier and more cost-effective to integrate into your existing operations without the need for additional software licenses or complex setup.

Whether your mine uses Datamine, Surpac, or another planning system, Unison can connect on the fly. This real-time data flow enables dynamic scheduling and optimization without costly and difficult custom integrations. This makes it a practical option for both small and large-scale mines.

YCP Unison offers live data feedback to control room operators, shift bosses and maintenance teams. This level of real-time transparency allows teams to make faster, more informed data-driven decisions for optimal resource allocation. Our algorithm ensures that mining units are allocated efficiently, avoiding over- or under-allocation.

Additionally, users are warned about potential bottlenecks from 1 hour to 14 days in advance, giving teams ample time to respond proactively.

With its flexible task and resource allocation system, driven by real-time data, Mine Scheduler is easily tailored to your unique mining operations and needs. Instead of relying on rigid pre-configured workflows, customize dashboards according to task schedules, reports, seasonality and benchmarks. The system adapts to your specific mining operation and not the other way round.

Who is Mine Scheduler for?

Mine Supervisors

Gain real-time visibility of resources at the mine face.

Short Term Planners

Visualize the 24-hour cycle to easily identify opportunities and interventions in shifts.

Control Room Operators

Identify systemic deviations quickly with a holistic data interface.

Mobile Maintenance Planners

Gain a bird’s eye view of equipment performance for proactive maintenance routines.