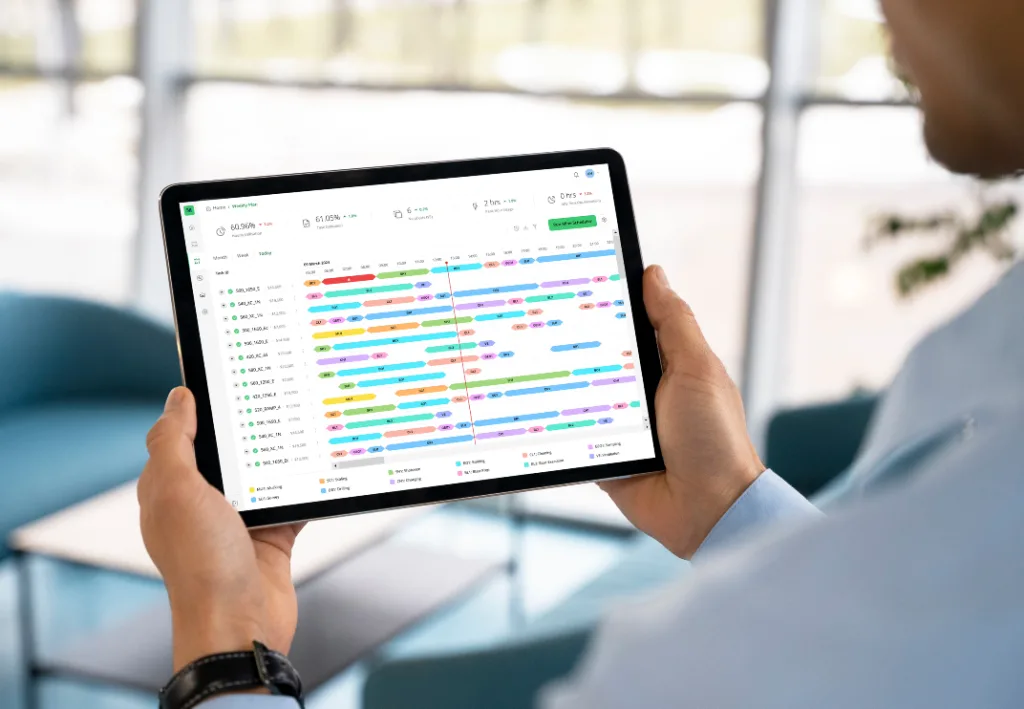

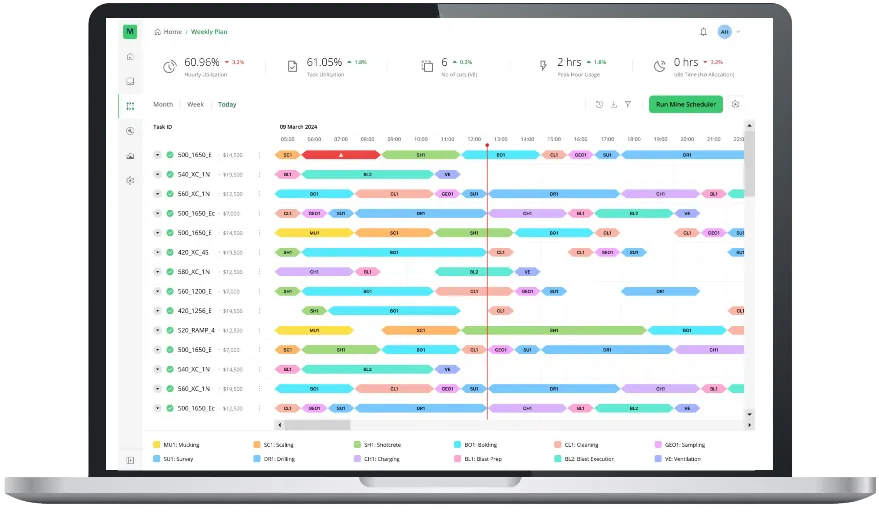

Leverage real-time data to allocate resources on-site

Platform Capabilities

Realtime Feedback Loops

Access live data feedback for shift bosses, control room operators, and maintenance teams. This real-time transparency allows teams to make informed decisions faster and with greater confidence.

Mobile Accessibility

Shift bosses can make on-the-go decisions using mobile access to Unison’s scheduler. This level of mobility is rare in other short interval control systems, which often require users to be tethered to control rooms or offices.

Quartile Algorithm Optimizer

YCP Unison’s scheduler algorithm automatically adjusts mine plans to ensure realistic, achievable results, removing bias and manual guesswork which often lead to suboptimal or overly ambitious plans.

Benchmarking Against Performance Standards

Customize the system according to task schedules, reports, seasonality, and benchmarks. This ensures that the system adapts to your mining operation, rather than the other way around, and progress is monitored according to your mine’s specific goals.

A single source of truth across your teams

Mine face utilization over equipment utilization

The platform provides an integrated holistic view of your equipment data, mine sequence, KPIs and benchmarks to ensure the mine site is maximized, rather than viewing mine performance solely through equipment data.

Who is Mine Scheduler for?

Mine Supervisors

Gain real-time visibility of resources at the mine face.

Short Term Planners

Visualize the 24-hour cycle to easily identify opportunities and interventions in shifts.

Control Room Operators

Identify systemic deviations quickly with a holistic data interface.

Mobile Maintenance Planners

Gain a bird’s eye view of equipment performance for proactive maintenance routines.