We Identify Opportunities Across the Full Mining Value Chain

Our change management services span the entire mining value chain – from enhancing operational readiness in early-stage mine planning, to optimizing scheduling throughout operations for greater mine face utilization, maintenance routines and ore processing.

With our proven behavior methodologies in practice, companies have historically implemented and sustained changes made at every organizational level long after project closeout.

How We Can Help

YCP Unison provides advisory and consulting services across the full mining value chain, identifying opportunities at every stage of your mining operations for enhanced throughput and profitability.

Mine Planning

Mitigate early-stage risk and ensure operational readiness for your mine with prefeasibility and feasibility studies, critical path planning, a master schedule strategy and sequence optimization.

Drilling & Blasting

Optimize drill and blast performance and minimize rock fragmentation issues to reap significant dividends downstream.

Load & Haul

Effectively coordinate equipment and vehicle utilization, optimize the load-haul-dump cycle to reduce downtime and cost per ton.

Maintenance

Management

Estimate and schedule maintenance tasks by leveraging fully integrated data on technician availability and equipment data such as MTBF.

Supply Chain

Management

Manage procurement effectively and mitigate supply chain risks with spend cube analysis, tailored to your mine conditions and needs.

Processing

Plant

Improve gauging and calibration practices for enhanced ore recovery and product quality consistency.

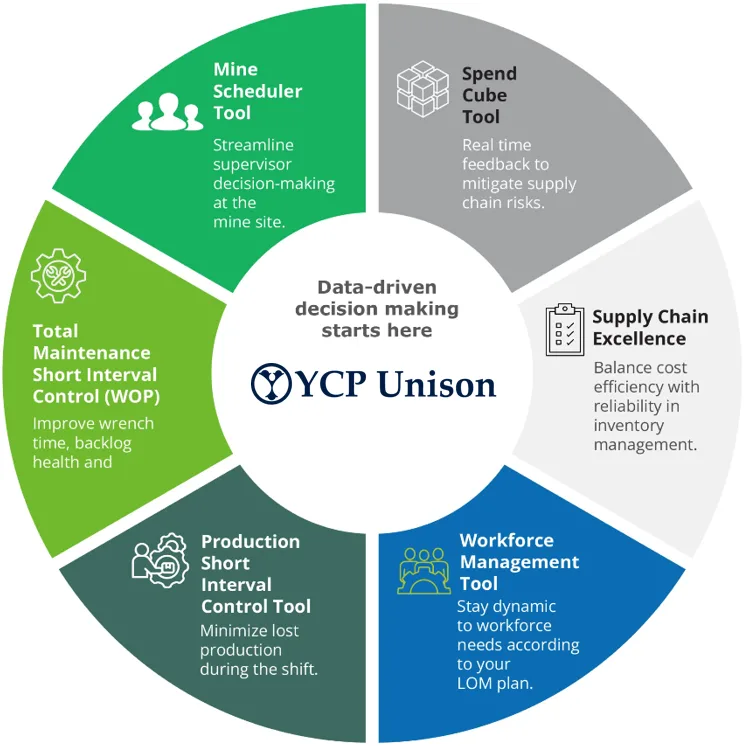

YCP Unison’s Data-Driven Approach

YCP Unison’s methodologies and tools effectively streamline the thousands of decisions that supervisors and mine planners need to make daily.

We meet key client challenges at every stage of the value chain with a data-centered approach, enabling decisions to be made based on reliable, accessible real-time data, rather than opinions and guesswork.